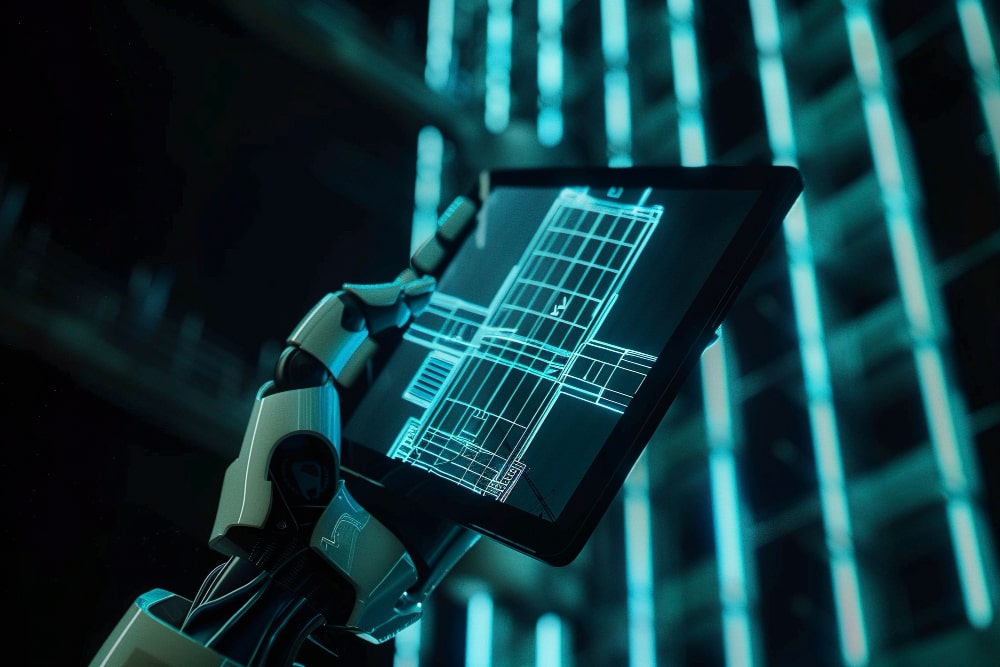

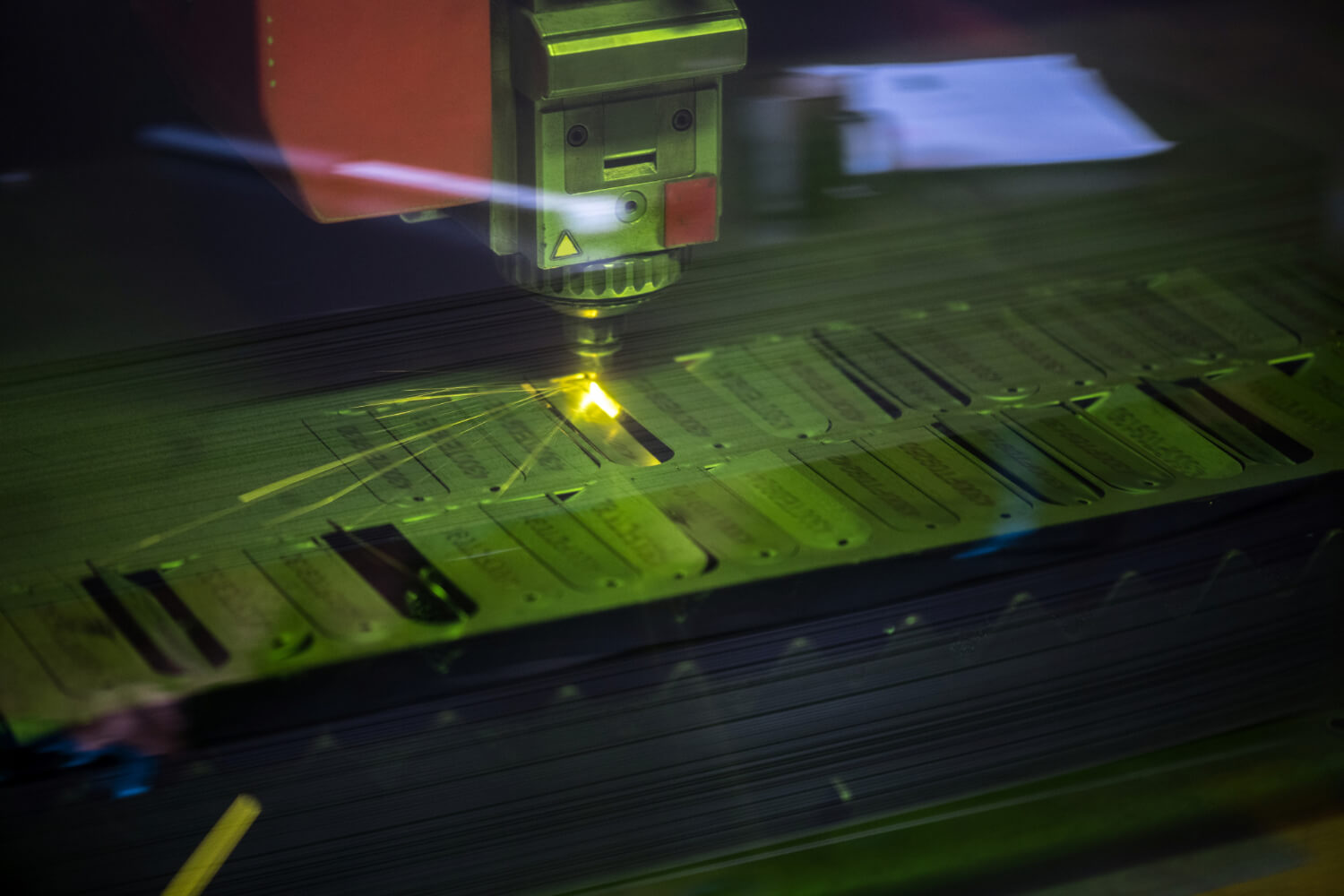

Benefits of using software in industrial welding

Industrial welding is a critical process in sectors such as automotive, construction, and machinery manufacturing. In this context, the use of specialized welding software has become a key tool to improve efficiency, quality, and the management of welding processes.