Welding is a critical process in manufacturing products that require high quality and precision. As demands for efficiency and quality increase, the incorporation of software in welding processes has become a key tool to optimize performance, reduce costs, and minimize errors. This article explores how digital solutions can revolutionize welding processes and provide competitive advantages for companies.

Importance of Optimizing Welding Processes

Welding is a complex process that combines technology, materials science, and skilled labor. Errors in this process can result in costly defects, material waste, and, in extreme cases, failures in final products. Therefore, optimizing these processes not only improves operational efficiency but also ensures product quality and customer satisfaction.

Optimization through software allows manufacturers to address key challenges such as:

- Reducing human errors: By automating tasks and improving real-time supervision.

- Enhancing product quality: By controlling critical parameters with high precision.

- Saving time and resources: By detecting issues early and optimizing production cycles.

Software Tools for Welding Optimization

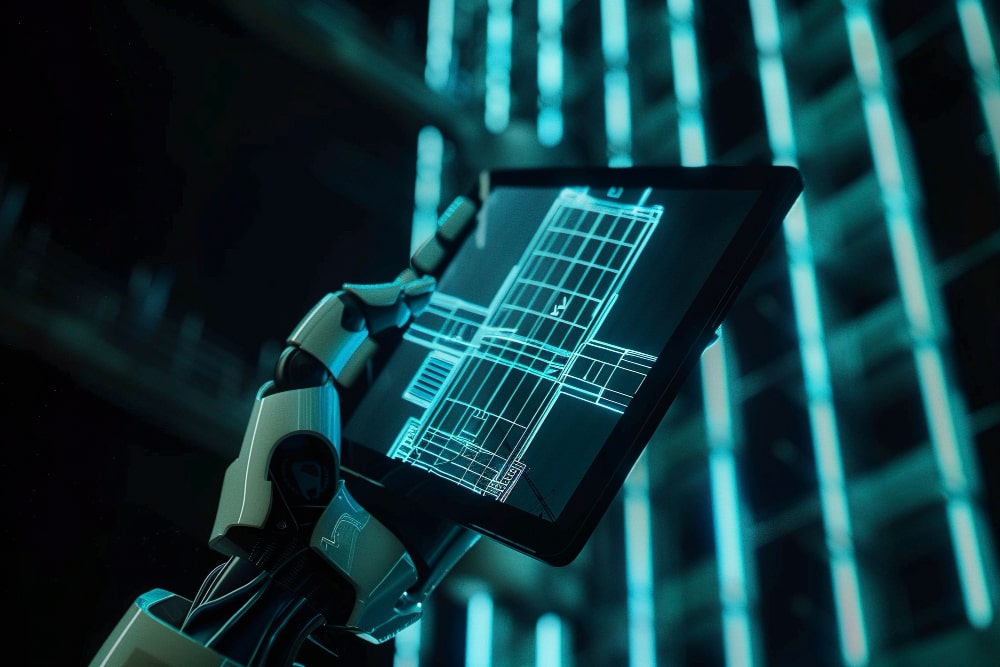

Welding-specific software encompasses a wide range of applications, from initial design to production monitoring. These tools include:

1. Welding Process Simulation

Simulation software allows engineers to predict the behavior of welded joints under different conditions. With these programs, residual stresses, deformations, and potential defects can be identified before actual welding is performed. This not only saves materials but also reduces trial-and-error time.

2. Control and Monitoring Software

Real-time monitoring is essential to ensure that welding processes stay within established parameters. Software-based control systems collect data from sensors and other devices to evaluate factors such as temperature, speed, and weld bead quality.

3. Project and Documentation Management

In large-scale welding projects, management software facilitates task organization, resource allocation, and compliance with regulations. It is also useful for maintaining a detailed record of Welding Procedure Specifications (WPS) and test results.

Benefits of Integrating Software into Welding Processes

The adoption of digital solutions transforms traditional welding processes by offering tangible benefits:

1. Process Standardization

Software ensures that processes are executed uniformly, reducing variations between operators and shifts. This is particularly critical in industries such as aerospace, automotive, and energy, where consistency is key.

2. Increased Productivity

By reducing the time needed for manual setups and diagnostics, software accelerates production cycles. It also enables the identification of bottlenecks and optimization of resource allocation.

3. Cost Reduction

Detecting defects at early stages and optimizing material usage significantly reduces production costs. Additionally, real-time monitoring minimizes waste and rework.

4. Compliance with Regulations

Software helps document and certify welding processes according to applicable regulations, ensuring that products meet quality and safety standards.

Challenges in Implementing Welding Software

While the benefits are clear, adopting software also presents certain challenges:

- Initial Costs: Acquiring and implementing these tools may require significant investment, especially for small businesses.

- Staff Training: Operators and technicians need to be trained in software usage, requiring additional time and resources.

- Integration with Existing Systems: Ensuring compatibility between software and already-installed hardware can be a complex process.

Future of Welding with Digital Technology

The welding industry continues to evolve towards greater automation and digital integration. Emerging technologies such as Artificial Intelligence (AI), Machine Learning, and the Internet of Things (IoT) promise to take welding process optimization to new levels.

For example, AI can analyze large volumes of data to identify patterns and optimize parameters in real-time. Similarly, IoT systems allow machines and devices to connect, enabling remote monitoring and control of the welding process.